Paper products

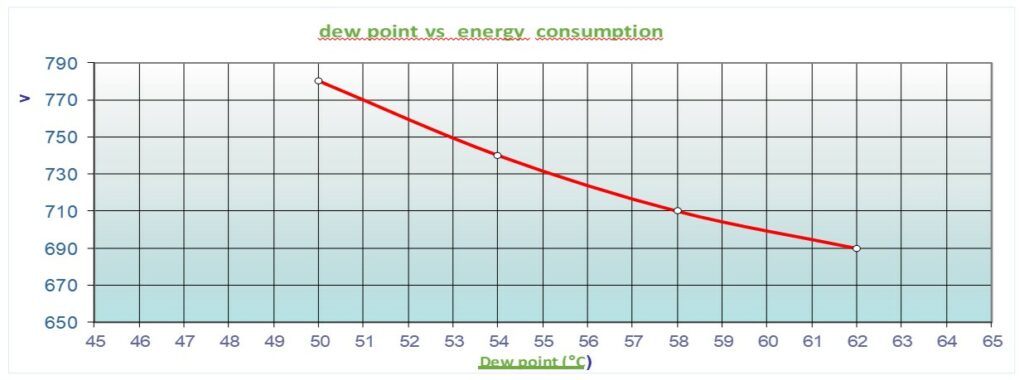

High dew point closed hoods and air system

The closed hood is a modern ted hood is a modern and very efficient design allowing Dew point service up to 62 °C.

Based on our experience, we can easily assume a running dew point of 58 °C (137 g/kg DA of water in the exhausts).

Characteristics

High efficiency

- The hood air quantity (exhaust and blowing) necessary is minimized compared to hood with lower dew point.

- Avoid leaks and condensation

- Perfect tightness

- Reduces fresh air infiltration

High performance

- Reduces sheet breaks

- Improves paper machine efficiency

Energy saving

- Reduces energy consumption

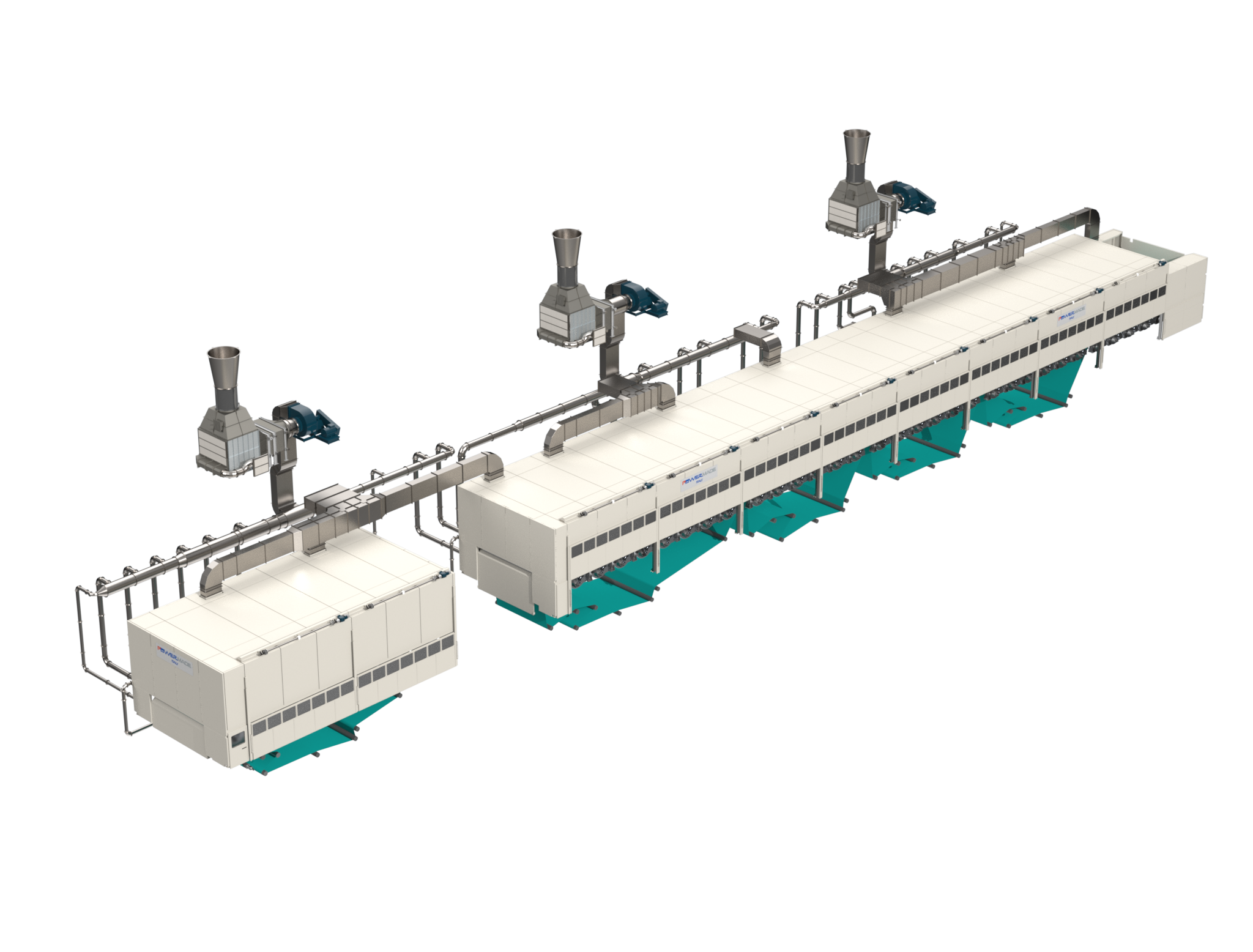

Design and characteristics of closed hoods

hood manufacturing

The closed hood is designed to reduce the excess ventilation, that is an important source of energy consumption. Less energy needed to extract the air means reducing fuel consumption and therefore optimizing energy efficiency.

- Roof panels can be dismantled to the entire width between the machine frame

- Easy dismantling with the hook of the travelling crane

- The construction is completely modular allowing an easy change of any of the dryer cylinders or dryer fabric transport rolls with the bridge crane. The top and lateral panels should be suitable to be disassembled manually by the operators without the need of the bridge crane

- The mechanical frame is designed in a way to support the wall for separation between the end of pre hood and beginning of post size hood.

- The doors are designed to allow the separation of hood in two units in front of area of Size

Central and lateral roof panels

- Sandwich panels made of anodized aluminium sheets enclosing a layer of high density rock wool

lining materials

- Aluminum

- Stainless steel

- Galvanized steel

- Central panels are easily removable with the crane for taking out rolls/dryer

- High stiffness of roof panel -walkable

- Lateral panels are removable for maintenance

POWERMADE S.r.l.

Via dei Bocchi, 323

55018 – Capannori (LU) – Italy

P. IVA/C.F. 02583810466

Utility