Tissue products

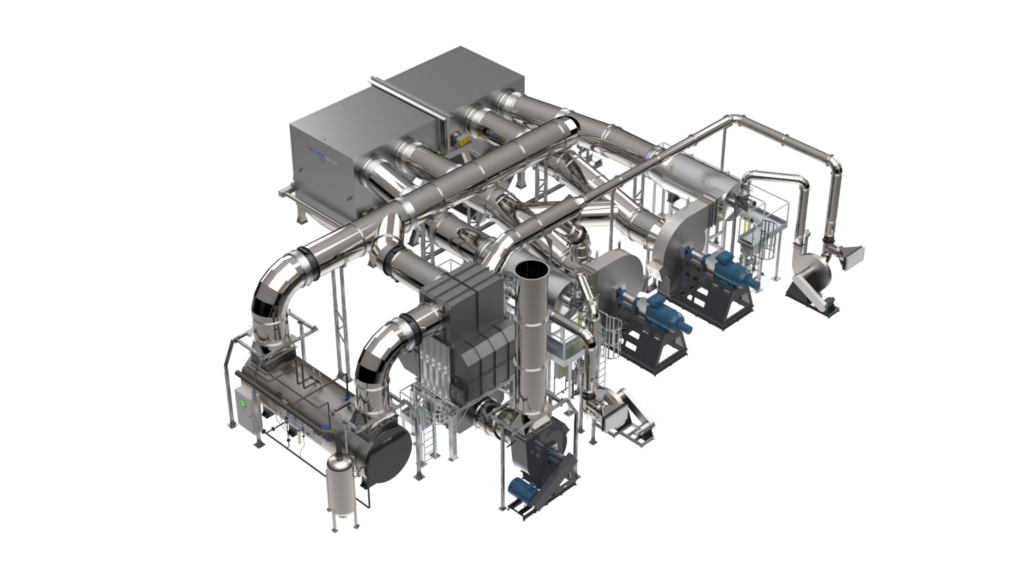

High efficiency Yankee hoods and air System

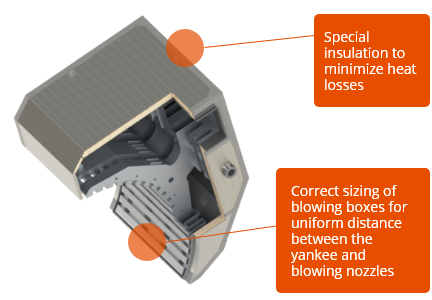

Yankee hoods are designed and built with the aim of minimizing pressure drops and with an insulation system that guarantees maximum efficiency.

The correct sizing of the blowing system in terms of speed and temperature allows the best penetration of the air on the paper sheet which guarantees optimal performance in terms of drying efficiency and uniformity.

Another key feature of the product is the minimized energy consumption and the possibility of energy saving by recovering the exhaust fumes to generate energy (steam) at no cost to be reused in the paper process.

Characteristics

High efficiency

- Minimum pressure losses as engineering of hood

- Air duct and special hood insulation

- Higher humidity at the extraction

High performance

- Correct sizing of blowing

- Right balance of blowing temperature and speed

Energy recovery

- Yankee heads insulation

- Recovery of exhaust air to pre-heat make up & combustion air and produce steam at high or low pressure

- Less energy consumption

- 2 Burners

- 2 Combustion chambers

- 2 Recirculating Air fans

- 1 Heat Exchanger Air-Air

- 1 Exhaust Air fan

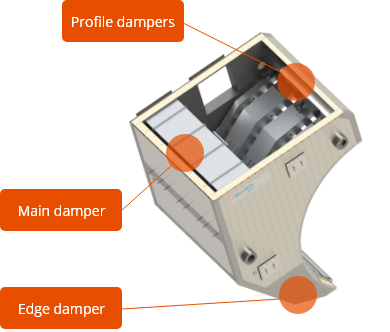

The hot air goes to the 1st dry half hood, the exhaust air goes partially to the exhaust fan and partially to 2nd ones of wet hood.

The exhaust of the wet hood goes to the heat exchanger and then to the atmosphere.

Allows to operate with different temperature, and air speed between wet and dry section, controlling the humidity in wet section.

burners COMMONLY USED for direct fire systems

- Low emission corner burners

- On line direct fire burner

Heat recovery system

- Modular type

- Easy to maintain

- Designed to improve

- High energy savings

POWERMADE S.r.l.

Via dei Bocchi, 323

55018 – Capannori (LU) – Italy

P. IVA/C.F. 02583810466

Utility