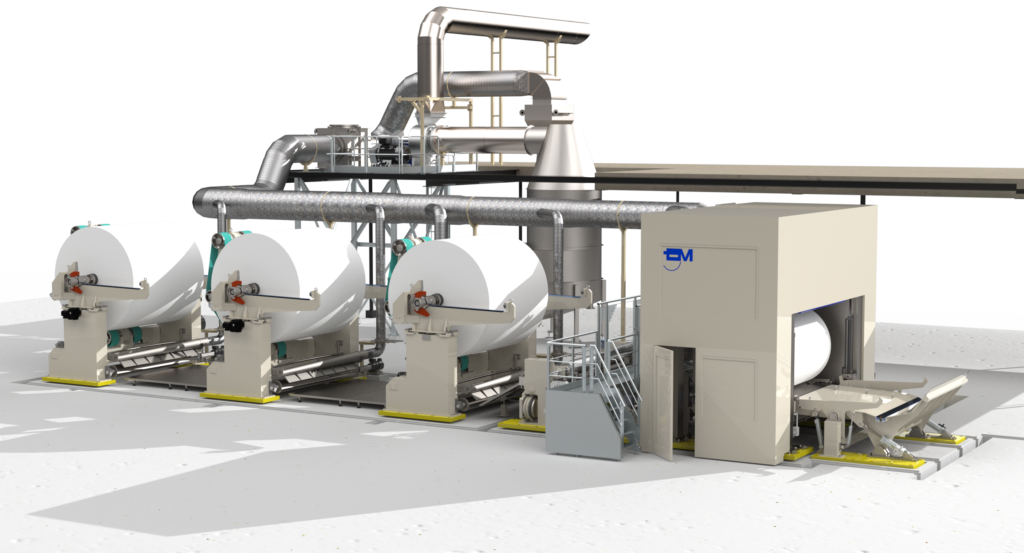

The dust removal system for winders and converting is designed to remove the airborne dust in the air generated by the unwinders and by the cutting and set-up system of the machine

This system has the main objectives of optimizing the runnability of the product, improving the quality of the finished product, reducing the risk of fire, and protecting the health of workers, thus improving the quality of the paper for the final product.

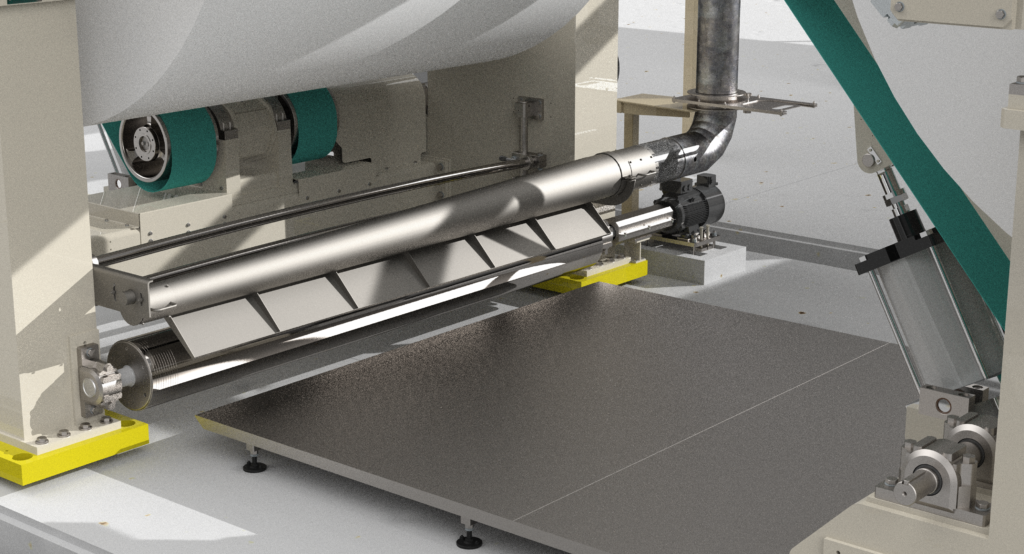

The dust released by the paper is sucked up by different types of suction boxes installed in various points of the machine and on the floor.

The geometry and position of these devices are designed to ensure maximum efficiency and not interfere with the operation of the machine. The dust captured by each suction box is conveyed to the main collector. The suction flow of each box can be balanced by manual dampers. If the sheet breaks, the suction is stopped.

The air flow is conveyed by a Venturi-scrubber or with a dedicated “Pulse jet bag filter” where the dust is separated from the air introduced into the atmosphere by a fan.

POWERMADE S.r.l.

Via dello Stadio trav. I, 56

55100 – Lucca – Italy

P. IVA/C.F. 02583810466

Utility

POWERMADE S.r.l.

Via dello Stadio trav. I, 56

55100 – Lucca – Italy

P. IVA/C.F. 02583810466