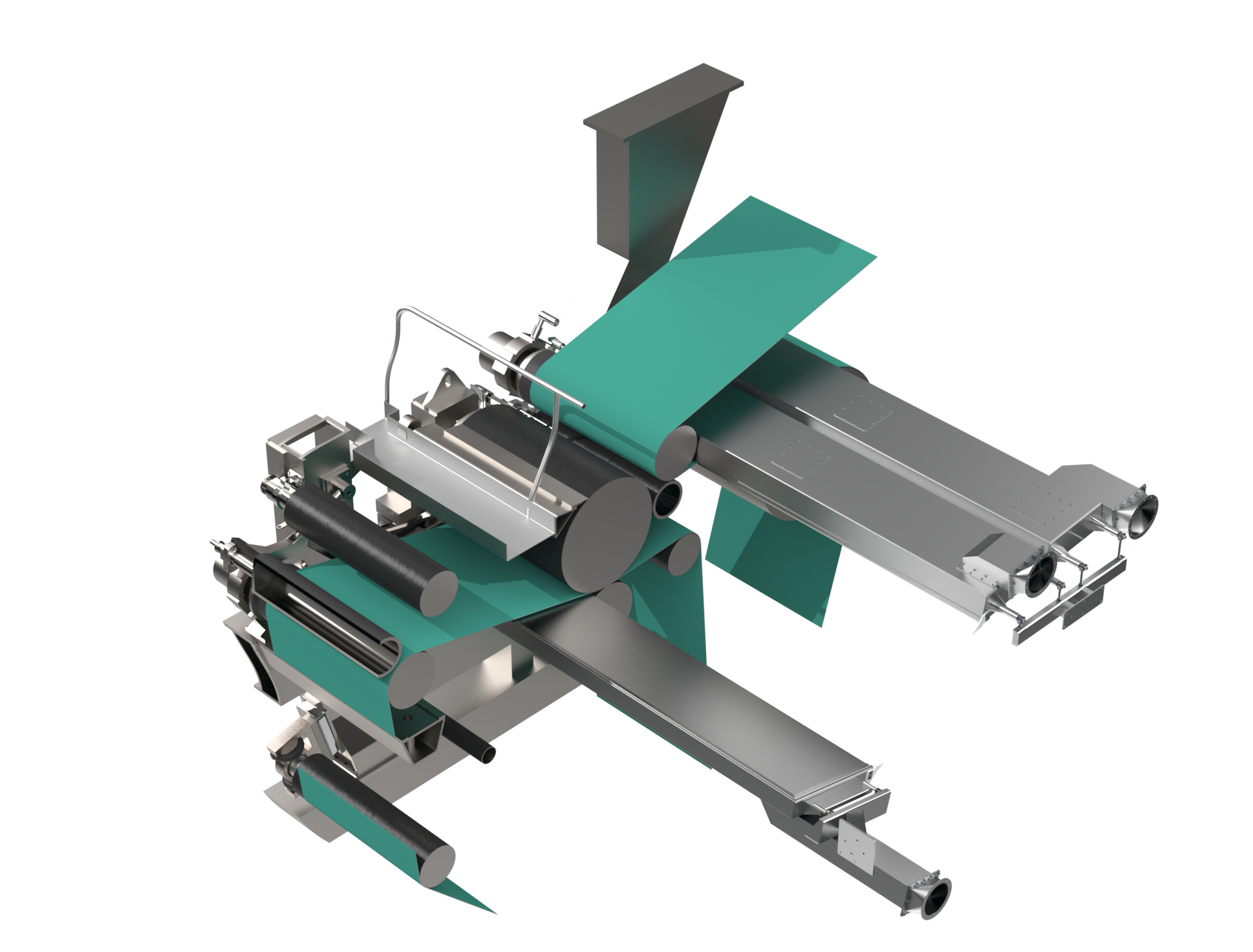

The sheet transfer and stabilization units are composed of a series of boxes which have the function of transfer and stabilize the sheet, wet and fragile, from the press section to the dryer, ensuring perfect flatness over the whole surface and avoiding shrinkage and breakage.

All components are made of 100% stainless steel and can be applied in multiple points as needed.

Transfer boxes use the low vacuum principle for stabilization

They can be supplied as “Suction type” when installed with stabilizer box so provide the same air system or “Blowing type” when applied with press run.

Full variability of web width – Edge perfectly spread – No shrinkage.

The “Blowing type” as direct web air removal complementing hood air exhaust useful in this critical zone.

Press run boxes generate the vacuum by Coanda effect.

They are equipped with 4-sides slot nozzle, blowing hot air at a minimum of 60°C.

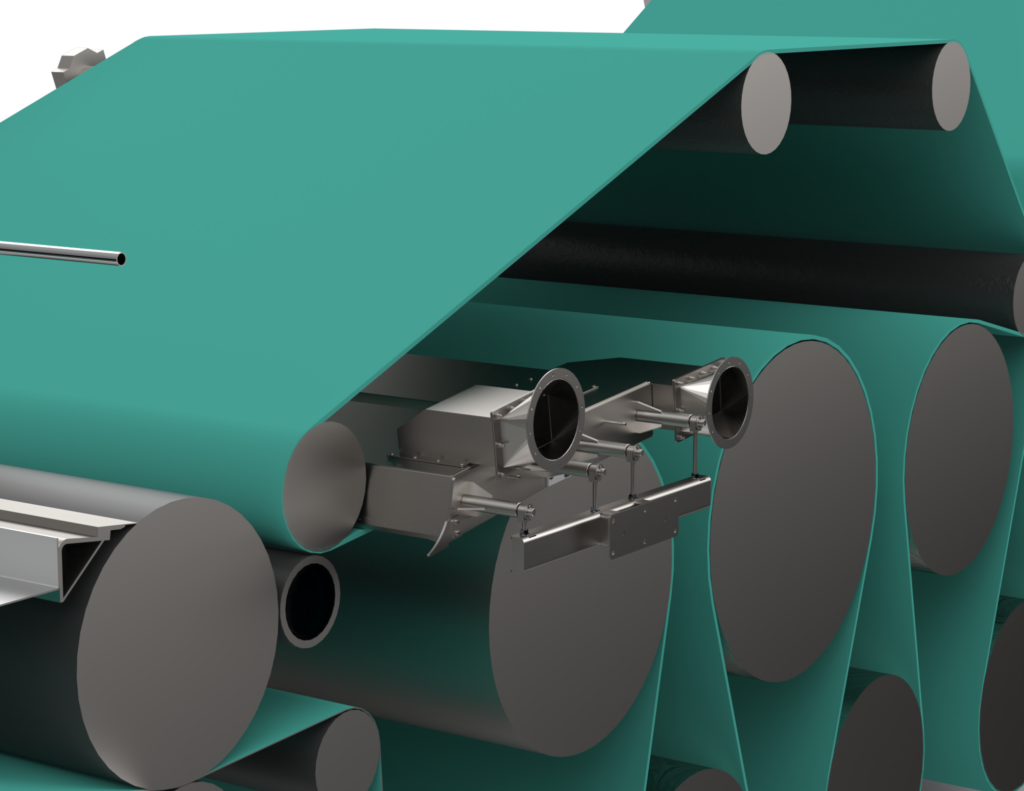

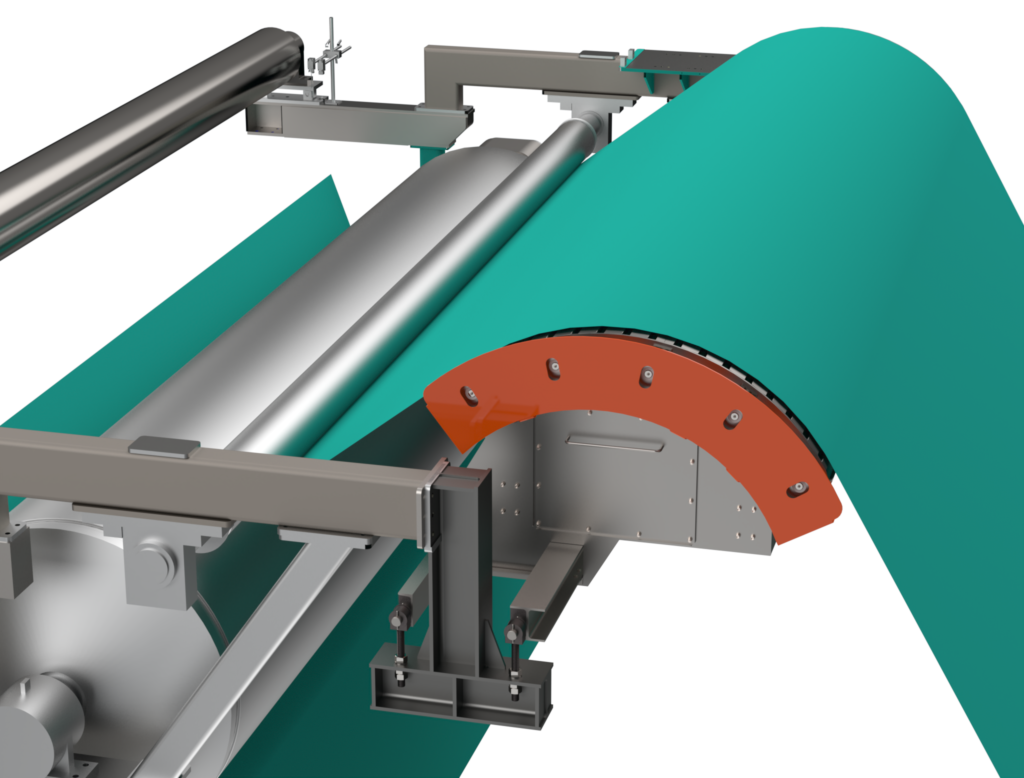

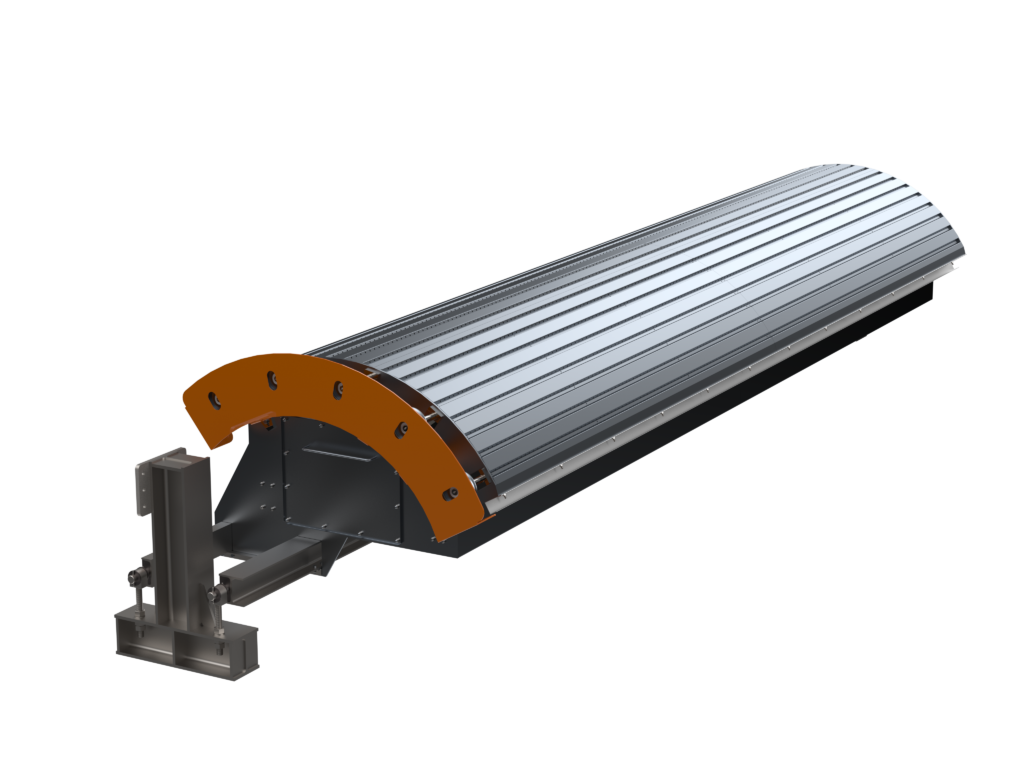

After the sheet has entered in the drying zone, a set of stabilizers assumes the transport of sheet in order to prevent the wet fragile paper sheet from any take-off and wrinkles.

The exclusive design of these stabilizers provides a high depression under the web, keeps the entire surface pulled onto the wire, and particularly prevents the edges from any floating movement.

Each Duo-stab is equipped with PTFE sealing to improve the vacuum effect of the system.

To improve the suction effect during the tail threading, a damper is installed on each duct connected to Duo-stab in order to suck air only at tail zone (making the paper sheet run easier and increasing machine efficiency).

To compensate the exhausted air from Duo-Stab boxes, some hot air (100/110°C) is re-injected via Warm-Keeper boxes located under Duo-stab.

The Warm-keepers are connected to a Blowing air duct from PRE ventilation group.

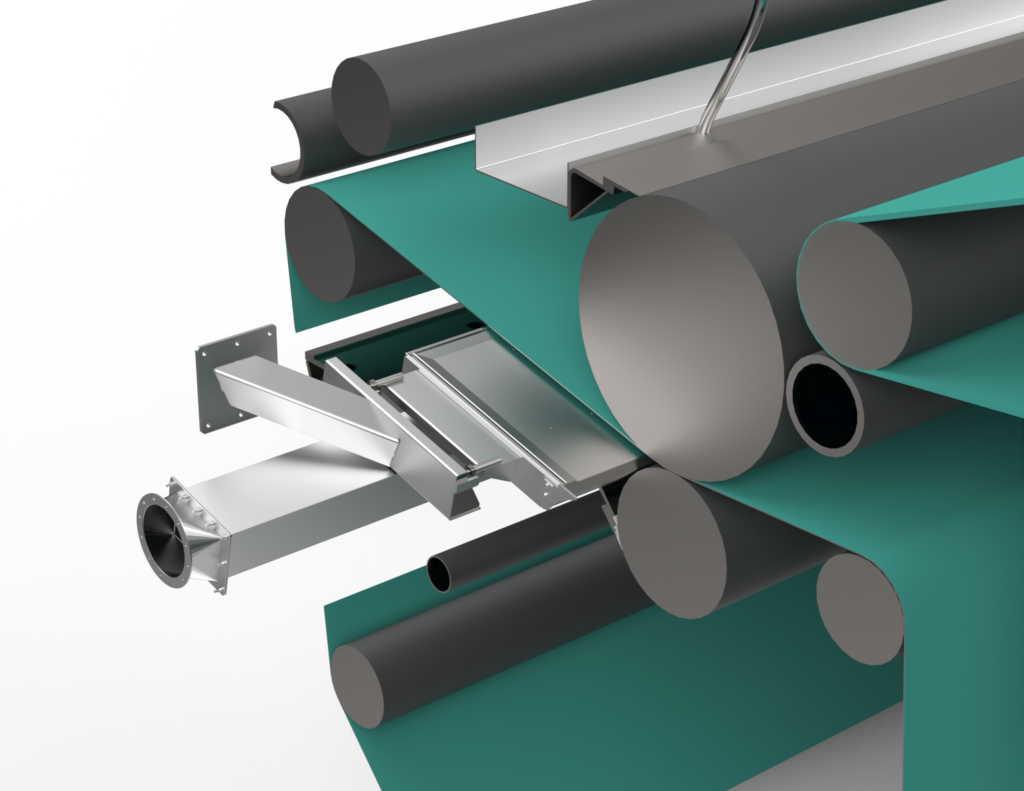

Mono stab boxes use the low vacuum principle for stabilization. They guarantee the perfect flatness of the sheet even on the edges and no shrinkage.

The suction solution as direct web air removal is a complementing of hood air exhaust useful in this critical zone.

Pocket ventilation are installed in the dryer section between cylinders to prevent stagnation of humidity over the sheet and prevent the wet fragile paper sheet from any take-off and wrinkles that cause sheet break to improve machine efficiency.

They are available in various versions depending on the type of application and the type of machine.

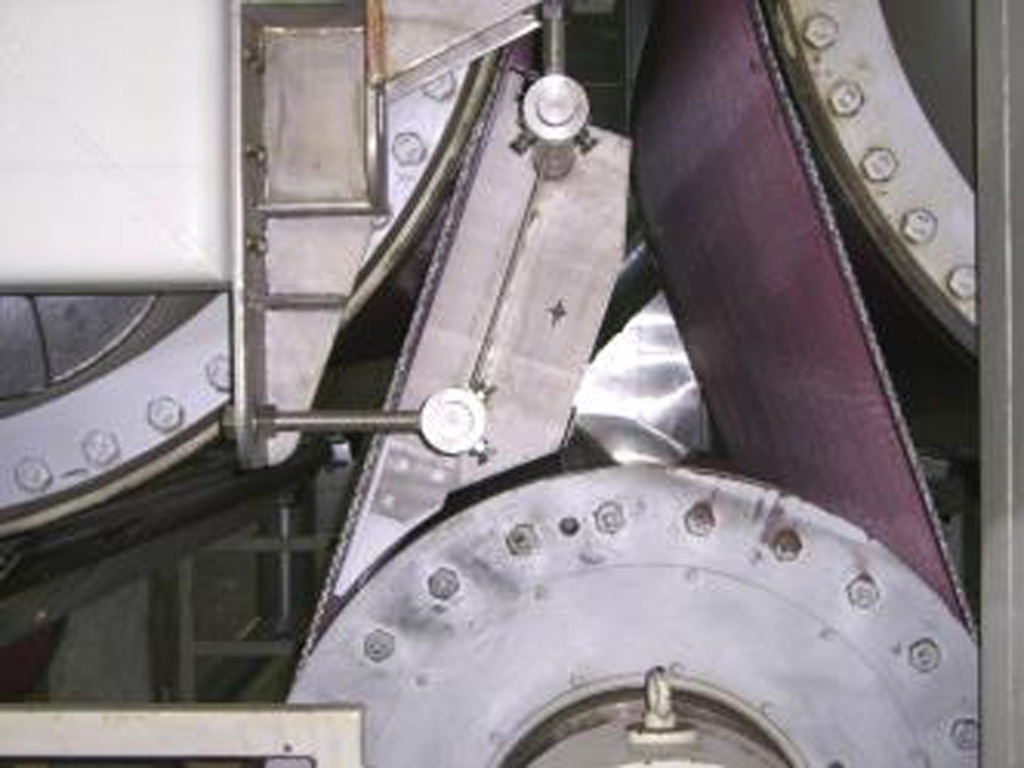

The main function of the Air-Turn is to support and deviate without contact the humid and coated sheet after Film-press or Size-press.

Our specific design enable the precise control of the air cushion pressure between the Air-Turn and the sheet surface.

It is equipped by independent sectors for blowing air in MD (machine direction).

To prevent the cooling of the paper, hot air (70° C) can be blown through a dedicated heating system.

The air is heated by mixing hot air from the heat exchanger of the closed hood and external air by automatic regulation.

The air flow is adjusted along the wire width on first start-up by the calibration of the internal windows by sliding dampers

POWERMADE S.r.l.

Via dello Stadio trav. I, 56

55100 – Lucca – Italy

P. IVA/C.F. 02583810466

Utility

POWERMADE S.r.l.

Via dello Stadio trav. I, 56

55100 – Lucca – Italy

P. IVA/C.F. 02583810466